John Deere 1450CWS, 1450WTS, 1550CWS, 1550WTS Combines Diagnosis and Tests Manual

(TM8235)

John Deere 1450 1550 1550cws Combine Service Repair Manual

Complete Manual Contents Breakdown:

Section 10: General Information

- Introduction, Specifications (Engine, Capacities, Weights, Gear Ratios), Serial Number Locations, Safety

Section 20: Engine and Emissions Systems

- Subsystems: Diesel Engine (Fuel System, Air Intake/Exhaust, Lubrication, Cooling, Electrical), Engine Control Unit (ECU) Diagnostics, Aftertreatment (DPF/SCR) Troubleshooting, Performance Tests

Section 30: Power Train

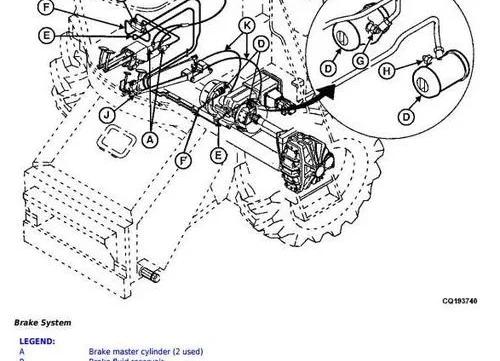

- Subsystems: Hydrostatic Drive System (Pump & Motor), Mechanical Drive (Differentials, Axles, Final Drives), Range Transmission, Parking Brake, Creeper Drive, Diagnostic Tests and Pressure Checks

Section 40: Hydraulic System

- Subsystems: Main Hydraulic Pump, Steering System, Header and Feeder Hydrostatic Drive, Reel and Platform Controls, Unloading System, Diagnostic Procedures and Pressure Specifications

John Deere 1450CWS, 1450WTS, 1550CWS, 1550WTS Combines Diagnosis and Tests Manual (TM4904)

Section 50: Electrical System

- Subsystems: Wiring Diagrams, Controller Area Network (CAN) Bus, Machine Control Unit (MCU) Diagnostics, Sensors, Switches, Lighting, Cab Instrumentation, Step-by-Step Circuit Testing

Section 60: Harvesting and Separating Systems

- Subsystems: Cutting Platform/Header (Feeder House, Sickle Drive), Threshing System (Cylinder, Concave, Rotor), Separator (Walkers, Straw Chopper), Cleaning System (Fans, Sieves), Adjustments and Timing Procedures

Section 70: Grain Handling and Storage

- Subsystems: Clean Grain Elevator, Grain Tank, Unloading Auger (Vertical and Extensible), Tailings System, Moisture Sensor Calibration

Section 80: Cab and Operator Station

- Subsystems: Air Conditioning/Heating, Displays (CommandCenter™ / CommandTouch™), Seat Controls, Joystick Calibration

Core Technical Resources (Integrated throughout or as appendices):

- Diagnostic Trouble Code (DTC) Lists: Complete tables for Engine, Transmission, and Machine Control with conditions, probable causes, and next steps.

- Symptom-to-System Troubleshooting Trees: Guided diagnostics for common operational issues (e.g., loss of power, poor grain quality, hydraulic chatter).

- Scheduled Maintenance Interval Charts: Service points at 10, 50, 100, 200-hour intervals, etc., including fluid specifications and filter part numbers.

- System Schematic Diagrams: Hydraulic flow and electrical circuit overviews.

- Adjustment Specifications & Torque Values: Critical settings for threshing, cleaning, and drive components.

- Pressure Test Port Locations & Specifications: For hydraulic and hydrostatic systems.

- Calibration Procedures: For yield monitor, moisture sensor, and speed settings.

This structure ensures comprehensive coverage of all major repairs, diagnostics, and maintenance, directly aligning with targeted user search intent for troubleshooting and technical data.