John Deere 160CLC Excavator Repair Technical Manual

TM1933

This manual is a comprehensive, system-by-system guide for major repairs, diagnostics, and specifications, structured to support professional technicians.

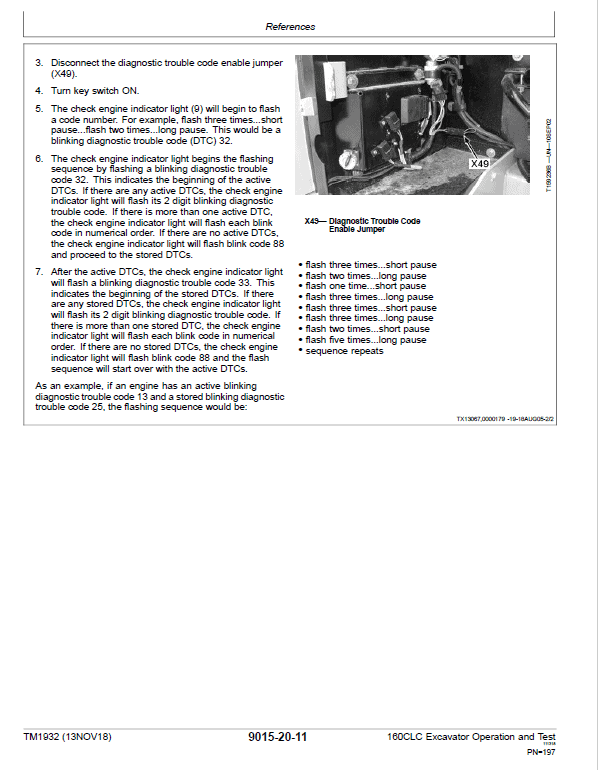

John Deere 160CLC Excavator Technical Manual

Detailed Table of Contents

Section 1: General Information

- Machine Identification & Serial Number Locations

- Technical Data & Dimensions

- Fluid Capacities and Recommendations (Hydraulic, Engine Oil, Coolant, Grease)

- General Safety and servicing Instructions

- Torque Specifications (Master List)

Section 2: Engine (John Deere PWX or equivalent)

- Engine Specifications & Performance Data

- Complete Engine Overhaul Procedures

- Subsystems: Fuel System, Lubrication System, Cooling System, Intake & Exhaust

- Turbocharger Service

- Engine Management & Electronic Controls (ECM) Diagnostics

John Deere 160CLC Excavator Repair Technical Manual

Section 3: Hydraulic System

- System Specifications & Schematics

- Main Hydraulic Pump (Variable Displacement Piston Pump) – Testing, Removal, Installation, & Adjustment

- Control Valves (Main & Pilot) – Disassembly & Assembly

- Hydraulic Cylinders (Stick, Boom, Bucket) – Rebuilding Procedures

- Swing & Travel Motor Service

- Hydraulic Testing & Troubleshooting (Pressure, Flow, Cycle Times)

Section 4: Electrical System

- Complete Wiring Diagrams

- Component Locations

- Power Distribution (Battery, Relays, Fuses)

- Machine Control Modules (MCM, ECM) – Parameters & Diagnostics

- Sensor & Switch Testing (Pressure, Angle, Speed Sensors)

- Cab Controls & Monitor (IntelliView Display) Diagnostics

Section 5: Power Train (Swing & Travel)

- Swing Gearbox & Swing Bearing Service

- Travel Gearcase & Final Drive Overhaul

- Travel Brake Adjustment & Service

- Track Frame & Undercarriage Components (Inspection & Adjustment Guidelines)

Section 6: Main Frame & Structures

- Upper Frame & Cab Mounting

- Lower Frame (Travel Frame)

- Boom, Stick, and Linkage – Inspection, Pinning, and Bushing Replacement

Section 7: Attachments & Options

- Hydraulic Hammer Piping & Circuits

- Quick Coupler Systems

- Blade & Tilt Bucket Circuits

Section 8: Diagnostic & Troubleshooting

- Machine System Diagnostic Codes (List of Codes, Conditions, and Probable Causes)

- Symptom-Based Troubleshooting Trees (e.g., “Weak Hydraulic Power,” “Engine Will Not Crank,” “Swing Drift,” “Abnormal Track Wear”)

- Electrical Diagnostic Procedures

- Performance Test Procedures (Engine, Hydraulic)

Section 9: Maintenance Interval Charts

- Detailed Lubrication & Maintenance Schedule (Every 50, 250, 500, 1000-hour services)

- Fluid Change Intervals & Filter Replacements

- Critical Bolt Retorque Schedules

- Inspection & Adjustment Checklists (Track Tension, Valve Clearances, etc.)

This structure ensures that a technician can locate everything from a routine maintenance task to a complete engine or hydraulic pump overhaul, supported by precise specifications, step-by-step procedures, and systematic diagnostic guides.