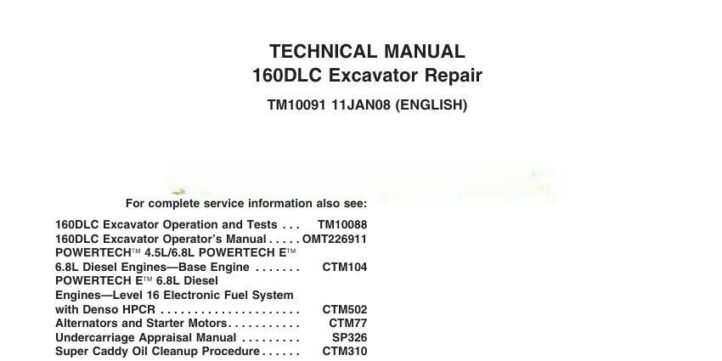

John Deere 160DLC Excavator Repair Technical Manual

TM10091

This official repair manual provides in-depth service, troubleshooting, and maintenance procedures for the John Deere 160DLC Excavator. It includes hydraulic system repairs, Engine overhauls, undercarriage servicing, electrical diagnostics, and structural component inspections to ensure peak machine performance.

File Format: PDF

Size: 10.12 MB

No. of pages: 406

Language: English

This outline will cover all major sections for repair, maintenance, and troubleshooting.

Technical Manual TM10091: Complete Table of Contents Breakdown

1. Front Matter & General Information

- TM Header: Equipment Nomenclature, Model, and TM Number.

- Safety, Warning, and Caution Notices (General and Specific).

- Equipment Description and Data: Specifications, capabilities, dimensions, weights, fluid types, capacities.

- Maintenance Allocation Chart: Who performs what level of maintenance (Operator, Unit, Depot).

- Standard Abbreviations and Definitions.

- Tools and Test Equipment (TMDE) Master List.

2. Operational Procedures

- Before, During, and After Operation Checks (PMCS – Preventive Maintenance Checks and Services).

- Starting, Running, Stopping Procedures.

- Basic Operator Controls and Indicators.

3. Unit-Level Maintenance Instructions (Core of the Manual)

- Chapter 1: General Vehicle Systems (Hull, Turret, Armament, if applicable).

- Chapter 2: Engine (Power Pack) Service. Subsections: Removal/Installation, On-Vehicle Repair, Troubleshooting (e.g., low power, no start).

- Chapter 3: Transmission and Steering Service. Subsections: Assembly/Disassembly, Adjustments, Troubleshooting.

- Chapter 4: Hydraulic System Service. Subsections: Pump, Valves, Cylinders, Accumulators, Lines, Troubleshooting (e.g., slow response, no pressure).

- Chapter 5: Electrical System Service. Wiring Diagrams, Component Location, Generator/Alternator, Starter, Battery, Lighting, Troubleshooting.

- Chapter 6: Fuel System Service.

- Chapter 7: Cooling System Service.

- Chapter 8: Suspension and Track (or Wheel) Service.

- Chapter 9: Fire Control / Auxiliary System Service (if applicable).

4. Support Sections & Appendices

- Appendix A: Lubrication Instructions (LO). Critical: A complete chart of all lube points, intervals, and applicable lubricants.

- Appendix B: Maintenance Allocation Chart (Detailed).

- Appendix C: Repair Parts and Special Tools List. Cross-referenced to the instructions.

- Appendix D: References (other related TMs, forms, etc.).

- Appendix E: Troubleshooting. A master section with symptom-based charts (e.g., “Engine Cranks But Does Not Start”) leading to probable causes and corrective actions, referencing the main chapters.

- Appendix F: Component/Circuit Diagrams (fold-out large schematics for electrical/hydraulic systems).

- Appendix G: Welding and Machining Instructions.